The 2010 Gulf of Mexico oil spill was the worst in

US History and had huge, immediate impacts on the coastal ecosystems of the area. 3.19 million barrels of oil were spilled into the Gulf, an amount that could clearly be seen from space, like this photo taken from the ISS on May 5th, 2004 demonstrates. Cleaning up this disaster is obviously of utmost concern, but current clean up methods are inefficient in so many ways.

|

Deepwater Horizon Oil Spill as seen from the ISS

Image Credit: NASA |

Physical barriers (floating booms) were used to try to surround the oil slick, but this method is only is successful when the water is calm and slow moving.

|

Booms used in an attempt to protect barrier island during Deepwater Horizon

Image Credit: Kris Krug |

Another method used was the use of dispersant, which helps the oil mix with the water instead of forming giant slicks. This is good in the short term, but just because you can't see the oil, it doesn't mean it's not there. The idea is that the smaller oil droplets will evaporate, and bacteria will slowly degrade the smaller oil droplets. However, the effectiveness of this is questionable. Dispersants can potentially enter the food chain and harm wildlife. Further, the dispersant-oil mixture with the water can be more harmful than just the oil itself!

This is where Penn State Professor Mike Chung comes into play. Chung began looking at hydrogels, the polymers in diapers that absorbs children's unfavorables. The issue with this is that it absorbs water as well as oil, and it disintigrates after it absorbs water… not super useful. Luckily we've got some pretty smart cookies here at Penn State, so Chung's lab was able to create a new material that meets all of the criteria.

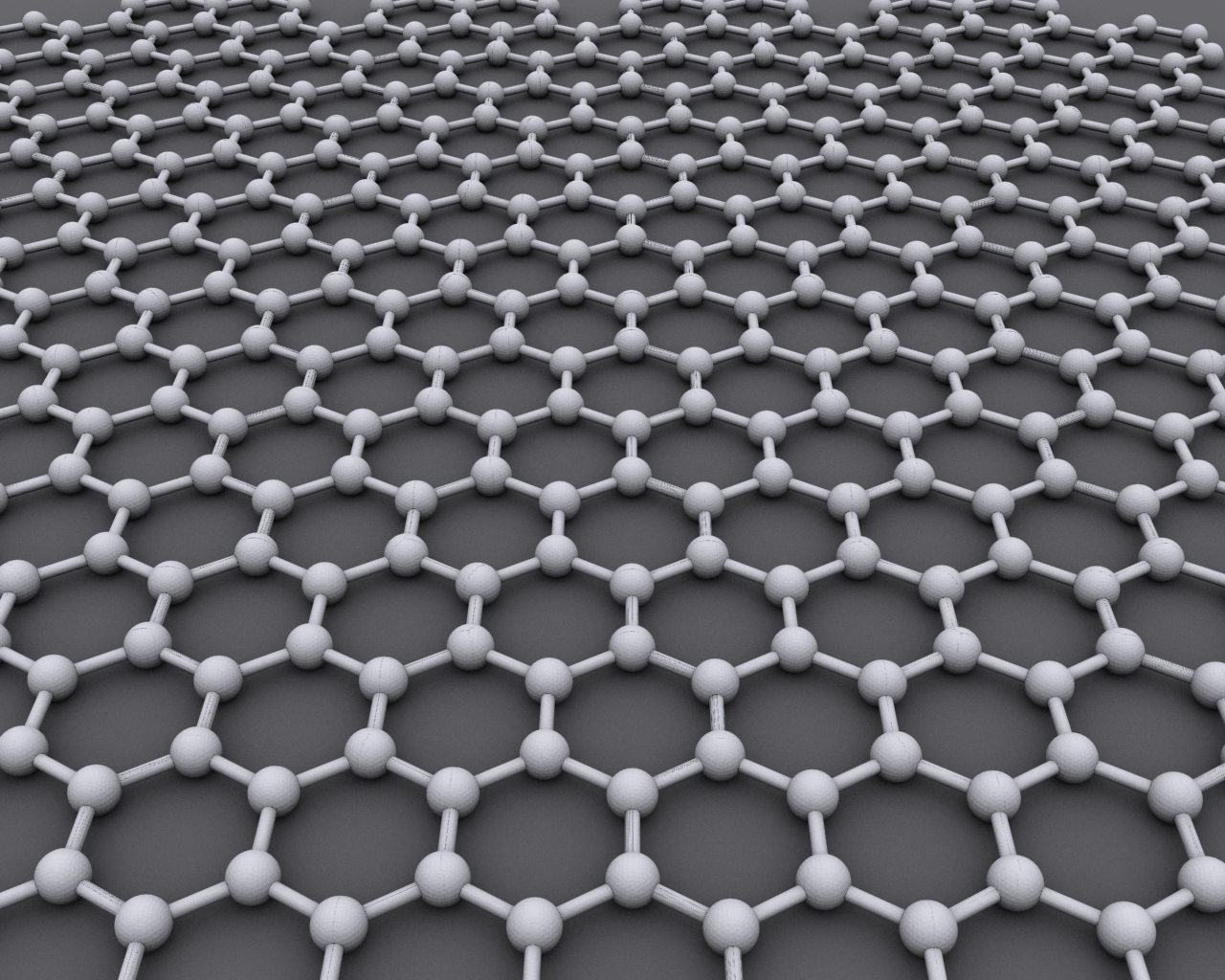

It's called PetroGel™(it's trademarked and everything!), and it's wonderful. Structurally, it's a low density polyolefin (polymers produced from

alkenes), which pretty much means it's a type of plastic. Functionally, the polymer can absorb 10 times its volume in crude oil in 10 minutes. In 24 hours, it can absorb

40 times its volume, and it doesn't absorb water. Even better, the material stays as a solid after absorbing the oil, making clean up a breeze.

|

PetroGel absorbing diesel gas

Image Credit: Penn State |

As plastic is an oil product, the gel along with the oil that it absorbs can be refined just like regular crude oil. That's 3.19 million barrels of crude oil that could have been saved and used in the Deepwater Horizon oil spill. At $46.26 per barrel at the time of writing this, that's a little under 150 million dollars.

To top it all off, polyolefin polymers are rather inexpensive, and it is predicted that in large scale production the product could cost less than $2 per pound. PetroGel™is an economical as well as an environmental win.

PetroGel™will undergo more rigorous testing with the US Dept. of the Interior's Bureau of Safety and Environmental Enforcement starting this

winter, so maybe we'll see Penn State's developments used in the next inevitable oil spill.